In today’s fast-paced and competitive market, designing high-quality electronics hardware is crucial for the success of any project. Whether you’re designing a complex embedded system or a simple PCB, adhering to best practices is essential to ensure that your product is reliable, efficient, and meets customer expectations. In this article, we will explore the top five best practices for designing high-quality electronics hardware.

- Plan for Design for Manufacturability (DFM) early on: Design for manufacturability (DFM) is the process of designing a product to be easily manufactured with minimal defects. Planning for DFM early on in the design process can save time, reduce costs, and improve product quality. Consider the manufacturing process, materials, and components while designing, and work closely with your manufacturer to optimize the design.

- Use Industry-Standard Design Tools: Using industry-standard design tools like Altium Designer, Eagle, or KiCAD can ensure compatibility with other design software, reduce errors, and streamline the design process. These tools have features like auto-routing, DFM checks, and error reporting that can improve design quality and save time.

- Keep your designs simple: Simple designs are easier to manufacture, test, and maintain. Avoid over-complicating your design with unnecessary features or components that can increase cost and complexity. Use standard components and avoid proprietary designs to ensure compatibility and availability.

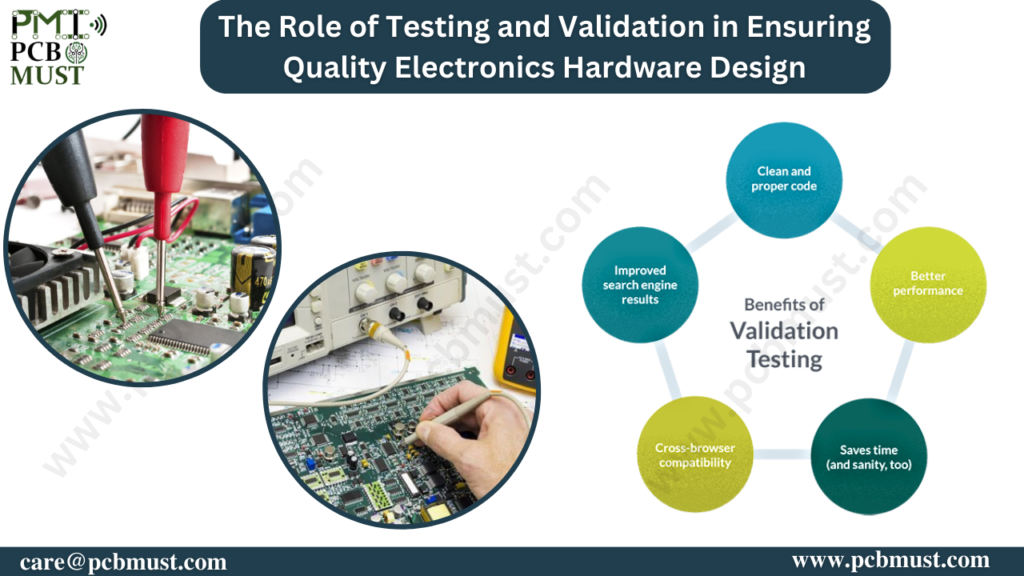

- Test and Validate your Design: Testing and validating your design is crucial to ensure that it meets the required specifications, standards, and regulations. Use simulation tools, prototyping, and testing methods to validate your design before production. This can help catch errors early on, improve reliability, and reduce rework.

- Document your Design: Documentation is an essential part of the design process. It helps in maintaining the design, troubleshooting, and future modifications. Document all aspects of the design, including schematics, bill of materials, fabrication files, and testing procedures.

In conclusion, designing high-quality electronics hardware is a challenging task that requires adherence to best practices, industry standards, and collaboration with manufacturers. By following these top five best practices for designing high-quality electronics hardware, you can improve product reliability, reduce costs, and increase customer satisfaction.