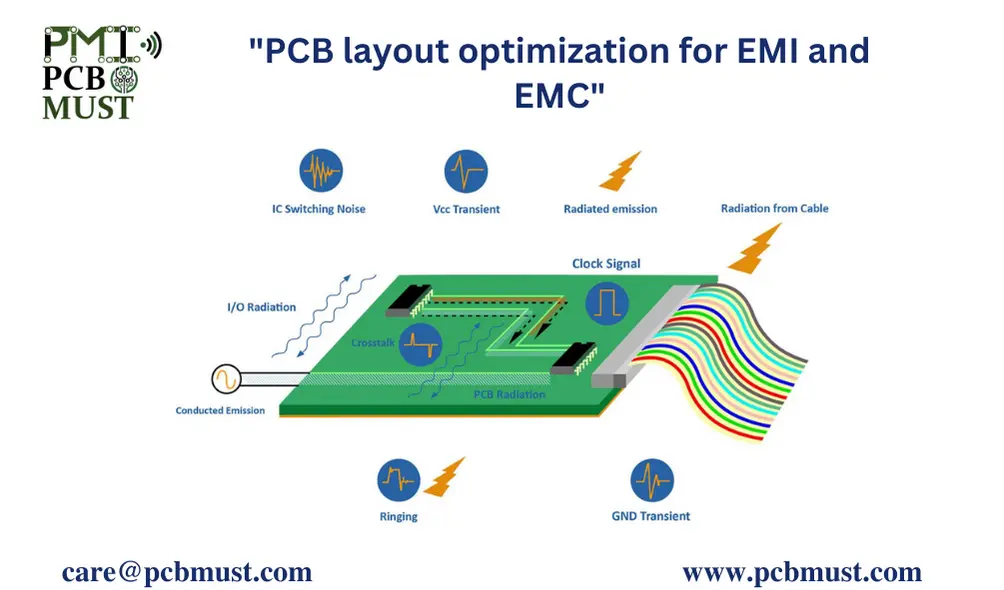

PCB layout optimization for EMI and EMC is an important aspect of electronics circuit design and PCB design. EMI (Electromagnetic Interference) and EMC (Electromagnetic Compatibility) are two critical parameters that must be considered when designing a PCB. EMI refers to the unwanted electromagnetic energy that can disrupt electronic systems and cause signal integrity issues. EMC refers to the ability of a device or system to function as intended in the presence of electromagnetic energy.

Optimizing the layout of a PCB can help to minimize the effects of EMI and improve EMC. This can be achieved through several different techniques, including:

1. Using Appropriate Trace Widths and Spacings

By using the correct trace widths and spacings, it is possible to minimize the amount of electromagnetic energy that is emitted from the PCB. This can be achieved by using wider traces for high-frequency signals and using smaller traces for low-frequency signals.

2. Implementing Ground Planes and Power Planes

Ground planes and power planes can help to reduce the amount of electromagnetic energy that is emitted from the PCB. By providing a low-impedance path for electromagnetic energy to flow, these planes can help to reduce the amount of EMI that is emitted from the PCB.

3. Using Shielding and Filtering

Shielding and filtering can also help to minimize the effects of EMI and improve EMC. By using shielded cables and filtering components, it is possible to reduce the amount of electromagnetic energy that is emitted from the PCB.

4. Using Proper Component Placement and Routing

The placement and routing of components on a PCB can also have a significant impact on EMI and EMC. By placing components in a way that minimizes the distance between them, it is possible to reduce the amount of electromagnetic energy that is emitted from the PCB.

5. Following Standard Guidelines

There are industry standard guidelines and regulations such as ISO 11452 and CISPR 32 which should be followed while optimizing the layout of a PCB. Following these guidelines can help to ensure that the PCB meets the necessary requirements for EMI and EMC.

“Pro tip: PCB layout optimization is key for reducing EMI and EMC issues. Using a combination of techniques such as proper grounding, shielding, and trace routing can greatly improve the electromagnetic compatibility of your circuit. If you want to develop a EMI and EMC Certified PCB talk to Experts.“